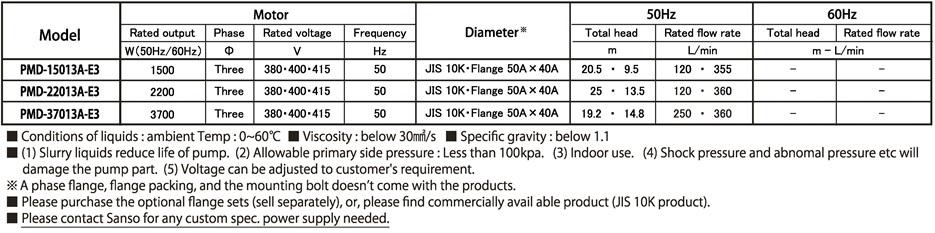

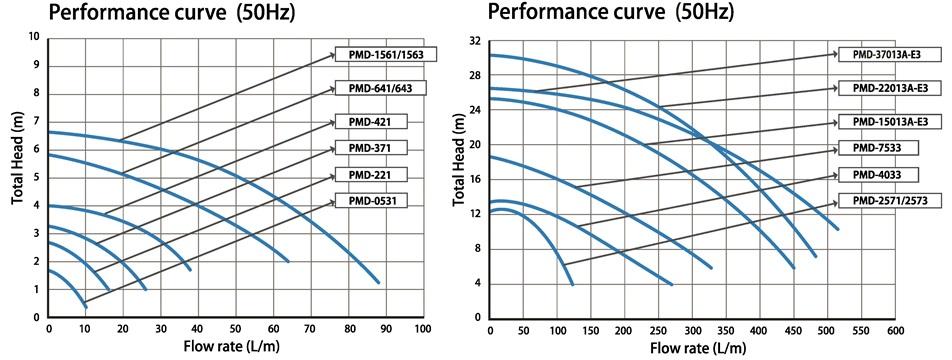

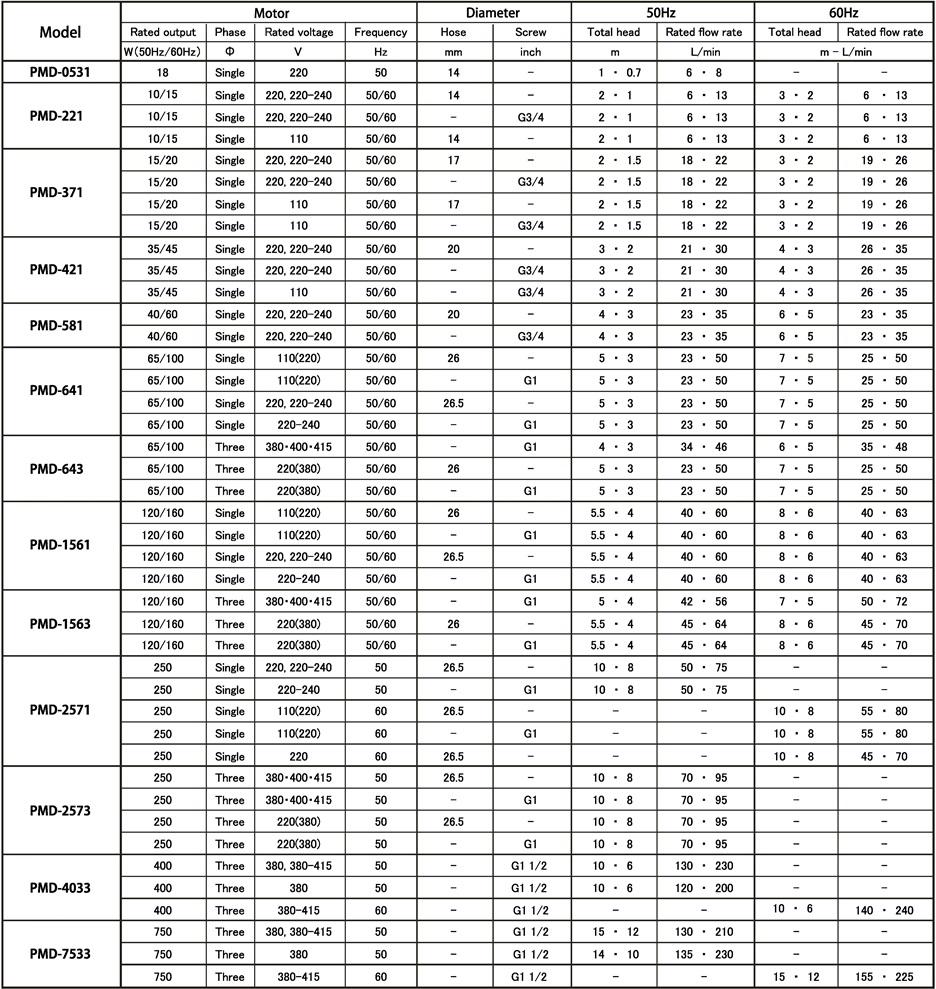

PMD-0531 PMD-221 PMD-371 PMD-421 PMD-581 PMD-641 PMD-643 PMD-1561 PMD-1563 PMD-2571 PMD-2573 PMD-4033 PMD-7533 PMD-15013A-E3 PMD-22013A-E3 PMD-37013A-E3

Compared to the conventional products, the pump efficiency increased by 35%.This type became smaller, lighter, 5-dB quieter and 50% reduction in vibration.

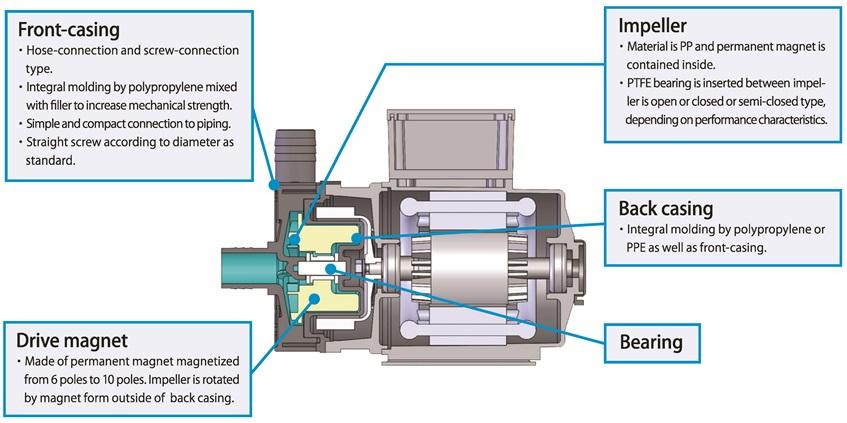

There is no liquid leakage due to no shaft seal part,As made of resin, this type is appropriate for transporting highly-corrosive special liquid.

This type is seal-less pumps based on the magnet coupling system. The pump section will never have liquid leakage, corrosion, dirt around the pump and troublesome mechanical seal replacement.

●Circulation of sea water,culture tank and water tank,etc.

●Drain chemical liquid,transfer of chemical liquid,etc.

●Waste water treatment equipment,Aquarium equipment,PCB equipment,Solar heating system,Filter,Bubble bath,Etching equipment,Printing equipment,Chillers,Cooling of NC machine,Ice maker,etc

・Chemical resistance must be verified before using the products by checking whether an intended purpose can be achieved with a preliminary test,etc.

・In order to use cold water, apply lagging materials and/or heat-insulating materials as measures against dew condensation if necessary.

| Fluid | Criterion |

|---|---|

| Sodium hypochlorite | Up to 5 ppm of concentration |

| Caustic soda | Up to 5% of concentration |

| Hydrochloric acid | Up to 30% of concentration |

| Sulfuric acid | Up to 10% of concentration |

| Citric acid | Up to 15% of concentration |

■The above corrosion resistance table shows the standards when a fluid temperature is normal (0 ~40℃)

Material of water contact part

| Part name | Classification 2 |

|---|---|

| Casing | PP(with glass) |

| Impeller | PP(with glass) |

| Pump shaft | Alumina ceramics |

| Thrust block | Alumina ceramics |

| Pump bearing | PTFE |

| O-ring | FKM |

TYPE Ⅰ

TYPE ⅠⅠ